I am so excited about the way the pantry is coming together! It’s amazing when the vision you have in your head for a space actually starts becoming a reality. I’ve finished the three floating shelves for the pantry and I can’t wait to share them with you. I am really happy about the way they turned out!

These floating shelves had three requirements. They had to be strong because I planned to put a lot of heavy stuff on them, they had to be thick and they had to be attractive. The internet is your best friend when it comes to pulling together ideas for a project. There are different ways to build floating shelves – I chose to go with what seemed to be the easiest way to get the strongest shelves! It isn’t really that difficult to get these beautiful shelves!

The pantry gets no natural light and it’s really hard to get good pictures with the light on. But I think they’re important to help you get a visual of the project so I included them!

Materials Needed for Three Floating Shelves

(You need to adjust the measurements to fit the size of your shelves) My shelves measure approximately 97 inches long, 15 inches deep and 3.5 inches thick. All of my wood cost around $132.90 or 44.30 for each shelf. I think that’s a pretty good price for these long, sturdy shelves!

- 9 – 2″ x 3″ x 8′ pine or whitewood board @ $2.60 each

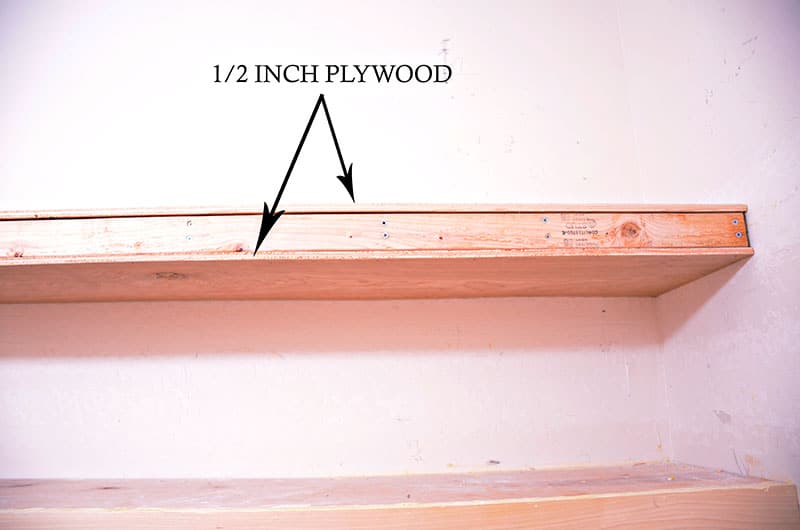

- 3 pieces of 1/2″ hardwood plywood material @ $25.00 each – Because I wanted my shelves to be 15 inches deep, I had the plywood cut into 14 inch strips.

- 3 – 1″ x 4″ x 10′ select pine or whitewood boards @ 11.49 each

- Brad nailer

- 3.5″ spax wood screws to screw frame into the studs.

- 2.5″ spax wood screws to screw supports into the front and back frame

- Wood glue

- Caulk if you are painting your shelves. (If you are staining, you need to make absolutely sure your measurements are precise. I’ve found that even if a caulk indicates it is stainable, there will be a detectable difference!)

Time to Put Your Shelves Together

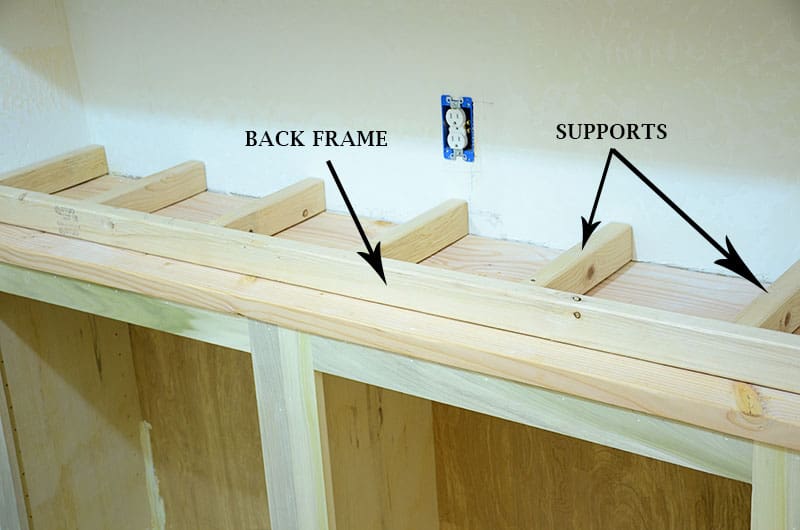

Cut your wood to size. Each shelf uses three of the 2” x 3” x 8 boards. One board for the front of the frame, one board for the back of the frame and one board for the supports. Because my shelves are 97 inches and my boards are 96 inches, no cutting for these were necessary for the front and back frame. I cut the supports 12 inches each. Since they fit inside the frames and the depth of each frame is 1 1/2″, the total depth of each shelf is 15 inches.

I didn’t use my Kreg jig because the frame is completely covered. I just drilled through the front frame directly into the support. Measure and place the supports evenly along the back frame.

Before you add the front of the frame, attach the back frame with the supports to the wall. Drill directly through the back frame into the studs. I used two screws per studs and added a metal L brace on each end of the frame for extra strength. I then drilled into the side wall directly into the studs. Be sure to use your level to make sure your shelves are plumb before you screw into the studs.

After this part of your frame is securely attached to the wall and level, attach the front part of the frame by screwing through the front frame board directly into each support. I used two screws per support. I checked for level each time I screwed into a support.

When Things Go Wrong (And They Will)!

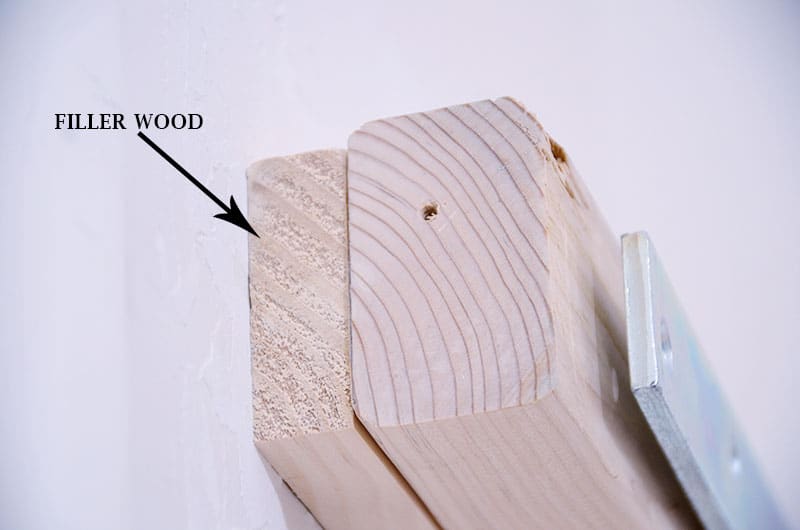

My front and back frame boards were one inch too short so I had to add a filler board at one end of the shelf. I drilled through the end support and the filler board directly into the stud.

It’s important to remember that when something doesn’t quite work (and this will happen!) – don’t panic or get discouraged. There are so many ways to compensate! Keep a clear head and you will figure it out!

Add wood glue to the top of the frame and add a piece of the plywood. For the bottom of the frame, I put the wood glue on the plywood panel, then attached it using my brad nailer.

Cut your 1″ x 4″ x 9′ to size. I cut mine to 97 inches since this is the length of my shelf. Use your brad nailer to attach it to the front of your shelf.

Tip: When I need a perfect fit, I always cut my wood just a little longer than I need. That way I can “sneak” up on the correct length. I then cut it down by hairlines until it is perfect. This method has never failed for me! You can always make wood shorter but you can’t add it back once you’ve cut it off. I got even more excited when I saw how this board made the shelves look – and that was before the finish work!

Finish it Off!

Use the filler of your choice to fill nail holes and any cracks. I had to add a small piece of plywood at the end of each shelf because of the shortage, so I used wood filler to conceal the seam.

I actually went overboard with the wood filler and added huge amounts to make sure none of my seams showed – I wanted it to be seamless. So guess what?? I was in sanding hell and I hate sanding! If I had been more careful when putting the shelves together, I could have avoided a lot of the sanding. Lesson learned!

After the filler was added and the shelves sanded, it was time for paint! My husband is the painter in our family, so when I say “we painted” I really mean “he painted! We used Behr Swiss coffee in semi-gloss left over from painting our kitchen cabinets. I love my new shelves! See them for yourself. (My pantry is not square – this wall really is angled so it’s hard to get a good picture!)

Okay, #pantrygoals going on right here! Your tutorial is great and the shelves turned out awesome! Love the wallpaper, too.

Thanks Laura…I went a little retro with the wallpaper!